After 45+ years in business, and thousands of customers around the world, the team at Epcon has so much to be grateful for… Wishing everyone a warm Holiday filled with Family, Friends and Gratitude.

Epcon holds several patents for thermal cleaning solutions. As industry experts in custom thermal deoilers, let our team show you solutions that are not only more cost-effective, but also environmentally sound alternatives to traditional industrial cleaning methods. Read more https://digitaledition.industrialheating.com/…/ther…/…

“Tackling the climate crisis requires everyone coming together to reduce pollution, and our industry partners have shown that we can accomplish this while improving energy efficiency and achieving millions in cost savings in the process,” said EPA Administrator Michael S. Regan. “Companies that have met the ENERGY STAR Challenge for Industry have demonstrated the business […]

Thank you for hard work day in and day out to serve our clients/customers and make this Epcon what it is! Happy Thanksgiving!

Epcon Industrial Systems is a known leader in designing and building ovens and oxidizers for continuous web processing applications, where the web can be either steel or aluminum, paper, plastic, fiberglass, and/or any composite material. The company’s challenge for an automotive industry customer was designing a high-velocity oven with forced convection to process 60-inch wide […]

Depending on your location, industry, or specific operating requirements, your custom industrial oven design can support a variety of different fuel sources. This can be electric, gas or even use an alternative fuel source.

2,500 SCFM Recuperative Thermal Oxidizer. See inside this 2,500 SCFM Recuperative Thermal Oxidizer, designed, manufactured, tested and installed by Epcon. This animation demonstrates how the airflows pass through the shell and tube heat exchangers for maximum operating efficiencies. The Recuperative technology is suitable for low VOC (Volatile Organic Compound) concentrations and processes requiring 24-hour […]

A simple rule of thumb to follow is that any engineered heating equipment that generates temperatures over 1000 degrees Fahrenheit is a furnace, and that which generates temperatures less than that is an industrial oven. But there are several other differences as well: Read more https://epconlp.com/products/process-heating-equipment/

The main difference between a Regenerative Thermal Oxidizer (RTO) and Recuperative Thermal Oxidizer is the different methods they use for heat recovery in the system. Regenerative Oxidizers pass hot exhaust gas and cooler inlet gas through one or more “heat exchanger beds” containing ceramic media. Recuperative Oxidizers pass hot exhaust through an air-to-air heat exchanger–typically […]

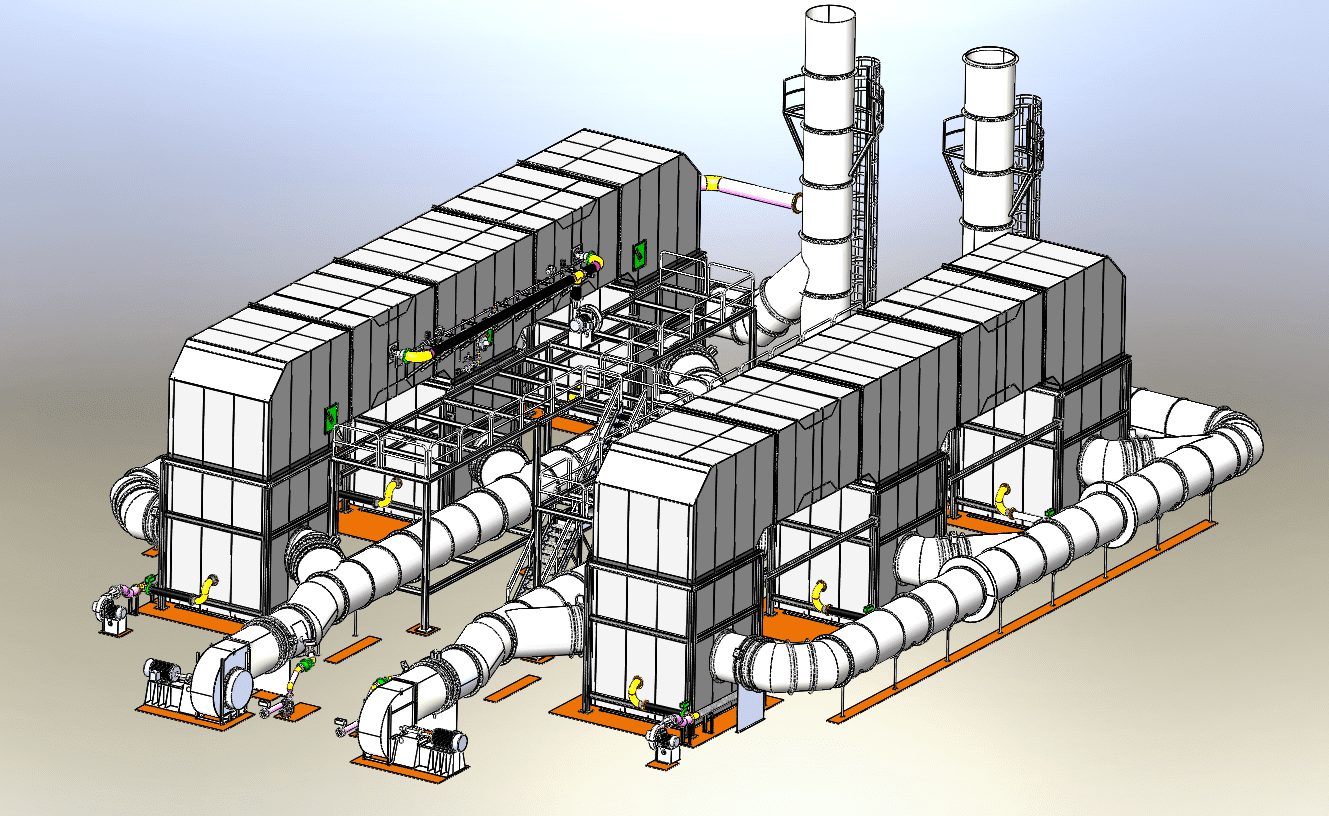

A new system comprising a curing oven, regenerative thermal oxidizer (RTO), and secondary and tertiary heat exchangers can help reduce operating costs while ensuring the safe removal of volatile organic compounds during composite bonding processes. Using this system significantly reduces a plant’s operating costs in terms of natural gas and electricity demands due to its […]